Defining Standards for Galvanized Structurals

At IM, we specialise in steel structurals.

We are specialists in galvanized pipes (called GP pipes or GI pipes) and coils, and we manufacture and maintain a wide variety of sizes within this niche. This focus allows us to deliver superior quality products and invest in innovations to deliver better.

The preferred brand for Dealers and Customers

Our products have a wide footprint and they are especially suited for coastal areas. We use only the best raw material, sourced from TATA Steel or JSW which provides a strong foundation. Each pipe is treated to be strong, durable and with a fine finish.

Durocoat technology that provides superior corrosion resistance and enhances aesthetics

120 GSM with 99.99% virgin zinc coating on each pipe (guaranteed by in-house galvanizing process)

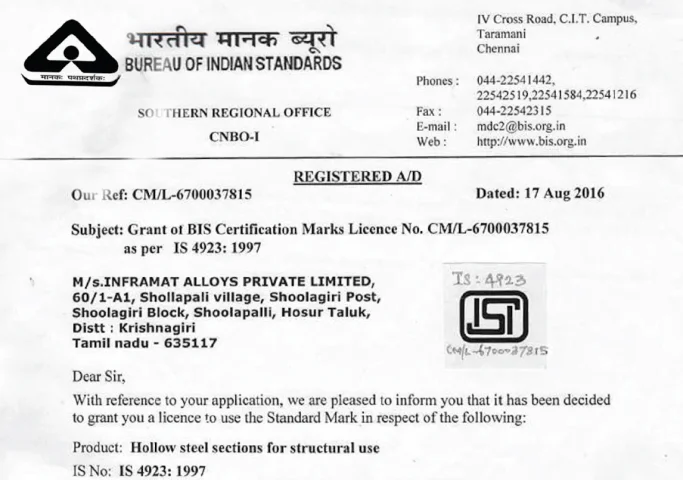

Embossed with ISI mark of 100% genuine quality

Passed through rigorous quality control to ensure thickness and weight

Unsure of what to look for when selecting pipes and coils?

Read our FAQs to help you make the right decision.

Process

Source high quality raw material (TATA/ JSW)

1/15

Quality inspection

2/15

Acid Wash (Pickling)

3/15

Strengthening strip (Cold rolling)

4/15

Shaping to Square, Rectangle, Round (Sizing)

5/15

Zinc coating (Galvanizing)

6/15

High frequency welding

7/15

Pipe Making (forming)

8/15

White rust prevention (passivation)

9/15

Zinc coating (Galvanizing)

10/15

White rust prevention (By DuroCoat Process)

11/15

Quality Check

12/15

Bundling, packaging and barcoding

13/15

Efficient logistics with tracking details

14/15

24/7 after-sales support

15/15

IM Advantage

All our products are manufactured in two state-of -the-art manufacturing units located near each other in Hosur, Tamil Nadu. Both units are ISI certified with routine and surprise checks by the bureau.