GI Coils

GI Coils

IM GI coils are made to meet domestic standards (15:277) and industrial standards (AST A653/ A653M). These coils are used in making GI pipes, solar profile sections, purlins (C Purlins) (Z Purlins) and various other general engineering purposes.

Our coils are coated with 120 gsm, unlike those available in the market which have a 70-80 gsm coating. This ensures that the coils maintain the standard strength and tenacity required for use.

We also take on custom orders for coils. The width, gsm of coating, and even technical features like strength, hardness and chemical composition can be customised as per requirement. Since we have in-house galvanization, we offer a minimum order quantity of 5 tonnes (versus 25 tonnes elsewhere) and a turnaround period of 3 days.

Process

Source high quality raw material (TATA/ JSW)

1/15

Quality inspection

2/15

Acid Wash (Pickling)

3/15

Strengthening strip (Cold rolling)

4/15

Shaping to Square, Rectangle, Round (Sizing)

5/15

Zinc coating (Galvanizing)

6/15

High frequency welding

7/15

Pipe Making (forming)

8/15

White rust prevention (passivation)

9/15

Zinc coating (Galvanizing)

10/15

White rust prevention (By DuroCoat Process)

11/15

Quality Check

12/15

Bundling, packaging and barcoding

13/15

Efficient logistics with tracking details

14/15

24/7 after-sales support

15/15

IM Advantage

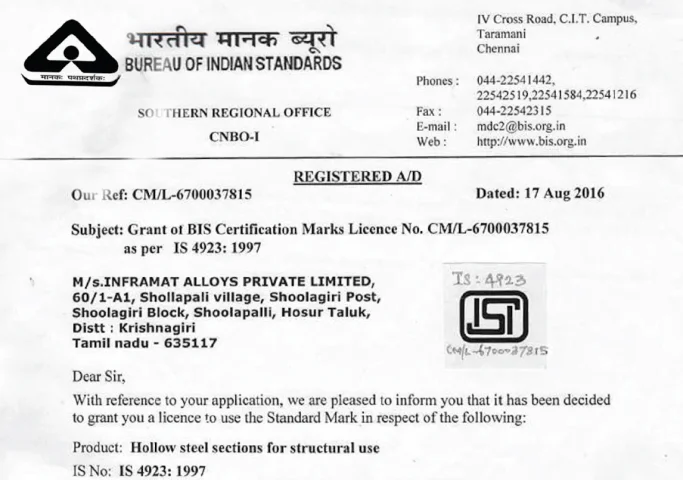

All our products are manufactured in two state-of -the-art manufacturing units located near each other in Hosur, Tamil Nadu. Both units are ISI certified with routine and surprise checks by the bureau.